NFPA certification is only where we start!

Ricochet manufactures all of our personal protective equipment (PPE) in an ISO 9001 certified facility in Philadelphia, PA. To meet NFPA 1999, 1951 & 1971 standards, Ricochet garments undergo numerous tests designed to guarantee durability and effectiveness of the barriers to liquid and liquid-borne pathogen penetration under the extreme conditions these barriers may face in the field. As tough as the NFPA standards are, creating PPE that is just "good enough" to meet the NFPA certification is not good enough for us. That’s why, at Ricochet, we engineer clothing that goes above and beyond the requirements of NFPA 1999, 1951 and 1971.

All sewn seams of the barrier component of each garment are heat-welded, using specially designed equipment. This process ensures the integrity of the barrier, allowing performance levels that meet or exceed the specific and exacting requirements of the NFPA Standards. Ricochet uses GORE-SEAM® tape, the most durable waterproof seam tape available, to seal all the tiny sewing holes in CROSSTECH® components of our garments. At Ricochet, we put in the extra effort to give you the extra security and confidence you deserve.

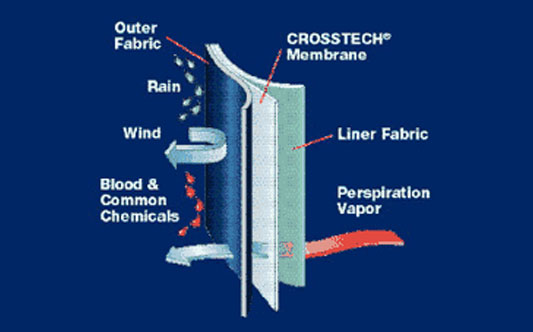

Over the years, Ricochet has evaluated many different barrier fabrics and, through our testing and experience, we continue to exclusively select GORE® CROSSTECH® fabrics, from W.L. Gore & Associates, Inc. Ricochet provides many levels of certified protection and we use GORE® fabrics, including GORE® CROSSTECH® EMS, GORE® CROSSTECH® S/R, GORE®, CROSSTECH® Black, GORE® CROSSTECH® 3-Layer, GORE® RT7100 and now GORE® PARALLON™ fabrics to meet these many levels of protection.

GORE® CROSSTECH® fabrics offer superior protection and are certified to meet the garment material requirements of NFPA 1999 - Standard for Protective Clothing for Emergency Medical Operations, NFPA 1951 - Standard on Protective Ensembles for Technical Rescue Incidents, and NFPA 1971 - Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting. These standards ensures that our PPE offers protection against flame, heat, water, blood and body fluids, as well as liquid chemicals such as battery acid, gasoline, and hydraulic fluid. GORE® CROSSTECH® fabric is fully waterproof and highly breathable, ensuring comfort in everyday use. It is highly vapor-permeable, allowing evaporated perspiration to escape at much higher rates than other films and coated fabrics. GORE® CROSSTECH® fabric keeps wearers drier, alleviating the potential for severe discomfort and heat stress problems. Like GORE-TEX® fabric, GORE® CROSSTECH® fabrics remains durably waterproof after exposure to flexure and abrasion in cold and wet conditions, and after exposure to contaminants such as oils, fuels, insect repellents, and other common chemicals. Gore’s manufacturing plant is ISO 9000 quality certified, ensuring the consistently high quality you expect from the inventors of GORE-TEX® fabric. At Ricochet, we know that the GORE® CROSSTECH® fabric membrane offers superior protection against blood, body fluids, and liquid chemical dangers.

The safety and comfort of your team is why we chose GORE® CROSSTECH® fabric as a critical component of Ricochet gear.

The links below provide more detailed information regarding design and certification levels of the various NFPA Standards. Feel free to contact Ricochet if you have any additional questions about how our garment designs meet these standards.

NFPA 1999

NFPA 1951

NFPA 1971

NFPA 1999 Bacteriophage Test

The NFPA 1999 Bacteriophage Test, or Biopenetration Test (ASTM 1671), uses a surrogate virus approximately the same diameter as hepatitis C, the smallest of the blood-borne pathogens. Pressure is applied on the challenge side (garment exterior fabric) and the reverse side (garment liner side), and scientifically analyzed for penetration to determine if the fabric is resistant to viral penetration.

This test precisely measures the ability of a garment that allows heat to pass away from the body through their three-layer composite that makes up their ensemble. To be more specific…it is the “breathability” of the ensemble. Generally, the higher the THL number, the more likely the system will be able to move excess body heat away from the wearer, reducing heat stress and fatigue. Higher THL values are created by lighter weight thermal liners and outer shells, but most effectively by high-performance moisture barriers such as Crosstech®. More massive thermal liners can inhibit the THL value and carry the high risk of elevating the body's core temperature to extreme levels.

The minimum THL requirement for a 3-layer ensemble is 205 W/m2. Again the higher the THL value, the better the breathability is for an ensemble.

Total Heat Loss has a direct relationship to Thermal Protective Performance (TPP), discussed in the preceding section. Researching and proper selections of TPP and THL values provide the best predictive indication currently available for safety and performance levels in firefighters protective clothing.

The selection process for outer shells, moisture barriers, and thermal liners can be challenging. Departments should carefully evaluate the various composites available for the best balance between THL and TPP values to best suit their climate and environment needs.

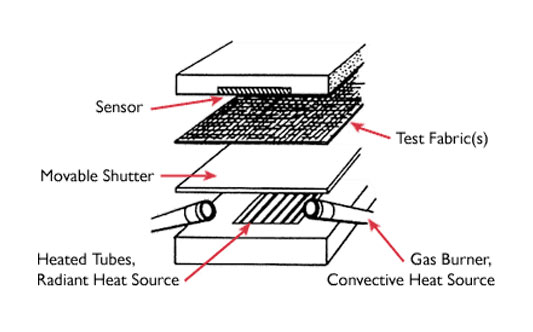

Thermal Protective Performance (TPP) test is a measurement of the time elapse for convective and radiant heat to penetrate through a composite system - Outer Shell, Thermal Liner, and Moisture Barrier - to damage the human skin. The composite is subjected to radiant heat & flame, simulating flashover conditions.

Below is an illustration of a standard TPP tester. The test runs all three layers in composite form - placed beneath the sensor, which records skin temperature. The layers are placed onto the machine in the same order in which they are worn in the protective ensemble, with the Thermal Liner next to the sensor, Moisture Barrier in the center, and the Outer Shell next to the energy source. A moveable shutter allows the technician to control the time and the amount of exposure; gas burners provide the actual flame. At the same time, the heated tubes provide the radiant heat, and a flashover situation can be simulated. The point at which heat transfer through all three layers is enough to cause second-degree burn is determined graphically by using a recorder chart of the sensor readings. During testing, the recording continuously traces the average temperature rise on paper, depicted as a curved line representing higher and higher temperatures as more heat penetrates through the sample materials to the sensor.

After testing is complete, its tracing is compared with a second curve, called the Stoll's curve, which shows the blister point of human skin as a function of heat and time. The point of intersection between these two curves is the actual TPP rating. To measure the exact time to burn, the TPP rating is divided in half to determine the number of seconds until the human tissue reaches second-degree burn. Thus, the NFPA minimum requirement of a TPP rating of 35 equates to 171/2 seconds until 2nd-degree burn occurs in a flashover situation.

A popular misconception is that if 35 is good, a rating of 40, 50, or even 60 must be better. It is important to remember, however, that the only way to increase your TPP rating is to add more insulation, usually by specifying heavier material components. Generally speaking, added insulation means increased weight of the total system, resulting in greater heat stress and fatigue for the firefighter. The question is…do you want the added seconds of protection in case of flashover or do you want a trade-off for a lighter weight system for breathability. These are questions that need to be addressed during your selection process.

Both THL and TPP tests are conducted on all 3-layers of the garment together. You can't take the values of one layer and add it to the values of another layer to get the result.

THL (Total Heat Loss) = “Breathability” Lighter weight/Thinner garments = Higher THL (Comfort/Breathability)

TPP (Thermal Protective Performance) = Thermal Insulation/R-Value Thicker/Heavier = Higher Thermal Protection (Susceptibility to Heat Stress)

There is an important inverse relationship between THL and TPP. The optimum values for each are needed to achieve both comfort and protection. Generally, as TPP goes up THL comes down, and as THL goes up TPP comes down, so the objective is to balance the two values that best suit the climate/environment needs. A lightweight ensemble, thin garment with high THL values may be comfortable but won’t offer you as much thermal protection. A thicker, heavier garment with higher TPP values can provide higher thermal protection but the susceptibility of heat stress and added weight can be dangerous. Departments should carefully evaluate the various composites available for the best balance between THL and TPP values to best suit their climate and environment needs. Moisture barriers will play a critical role in the breathability and THL value of the garment.

If you should have any questions or need assistance with the selection process, please contact us or a Sales Representative.

Conductive and Compressive Heat Resistance (CCHR)

The Conductive and Compressive Heat Resistance (CCHR) test is to specify minimums in protective insulation required in high compression areas. The requirement is that the CCHR rating of shoulder and knee areas, when compressed, must equal the established base garment rating. This is intended to ensure that the shoulder and knee areas will provide the same level of protection when compressed, as does the remainder of the garment. The test is run in both the wet and dry conditions.

The CCHR rating is the time in seconds to achieve a temperature rise of 24° C. The minimum requirement is 25 seconds, which is equivalent to testing a garment with a TPP value of 35 on a hot plate set at 280°C, under a pressure of 1/2 lb. per square inch.

The shoulder area is tested under 2 lbs. psi, which simulates a firefighter wearing a 40 lb. SCBA. And the knee area is tested under 8 lbs. psi, which simulates a 180 lb. firefighter when in a kneeling position.

The original requirement did necessitate an additional layer of insulation with certain composites, depending upon which composite the base garment was built from. However, Ricochet standard practice automatically adds a second layer of thermal liner in these high compression areas, to ensure we exceed the minimum requirements. Ricochet also offers a variety of options for the shoulder and knee reinforcement area that will exceed the CCHR requirements while offering higher THL’s and TPP’s in these critical areas.

Please be sure to contact a sales representative or contact us directly.

Why Outer Shell Materials Change Color

Outer shell materials used in the production of today's protective clothing are blends of very high-temperature resistant fibers, such as Nomex®, Kevlar®, and PBI®. These high-temperature blends are flame and heat resistant and have the ability to self extinguish when the source of ignition is removed. However, these outer shell fabrics can be difficult to dye. There are two different types of dyeing processes being used today, “Piece dyed” and “Solution Dyed or Producer Dyed”.

The traditional Piece Dyeing technology puts color on the fabric's outer layers (topical) using heat and pressure which damages the fibers and weakens the fabric. A color change to the outer shell material is generally indicative of some type of thermal exposure. The dye will typically burn off (disappear) when these materials see temperatures reach close to 450° F, with or without direct flame impingement. When a piece-dyed outer shell shows signs of discoloration due to high temperatures it is called dye sublimation. This can be a good indicator for the wearer to inspect their garment. Exposure to ultraviolet rays can also cause the material to weaken and fade.

Solution Dye or Producer Dye technology offers long-lasting, consistent color and outstanding strength performance against damaging ultraviolet rays and radiant heat. Solution-dyed materials introduces the dyes into the spinning solution prior to extruding the yarn so each fiber has color inserted throughout the fiber bundle in order to maintain the fiber strength and color. Solutions dyed materials offer enhanced colorfastness and will not see dye sublimation under high temperatures. Even though solution dye technology protects the fibers from UV, PPE clothing should never be stored or exposed to long durations of UV directly or indirectly.

Discoloration by itself is not necessarily a cause for alarm since the heat and flame characteristics are inherent to the material and cannot be washed off or worn out. However, any material should be checked for continued tensile strength whenever discoloration is noticed. This can be accomplished by placing manual pressure and pulling at the discolored areas in question. If the fabric can be torn, it should be immediately removed from service. If any outer shell material has been exposed to enough heat to cause discoloration, then the liner system should also be carefully inspected, especially the moisture barrier which is located closer to the outer shell. We recommend that if the outer shell has become discolored, the moisture barrier should be evaluated using the hydrostatic water test method.

Solution dye introduces the dyes into the spinning solution prior to extruding the fibers into yarns.